What must you know about finding a suitable valve to use?

Valves help to control the gas and liquid flow in all the processes and systems. You can find them in your homes, hospitals, and industries that you can avail of at Anix Valve. You are expected to see them anywhere, but finding the suitable valve for the job can be challenging. The choice of finding a valve will depend on the performance requirements of a system. These are the tips that will help you choose the suitable valve.

Look for special valve requirements.

Before you buy a valve, ensure it will work how you expect it to. You must ask yourself how long the valve will take to respond and how much pressure is needed to open it. Consider the open or closed valves because every valve will serve a different purpose. Making the right choice can enhance the reliability of the valve. It will depend on whether the valve is closed or open during the system operation.

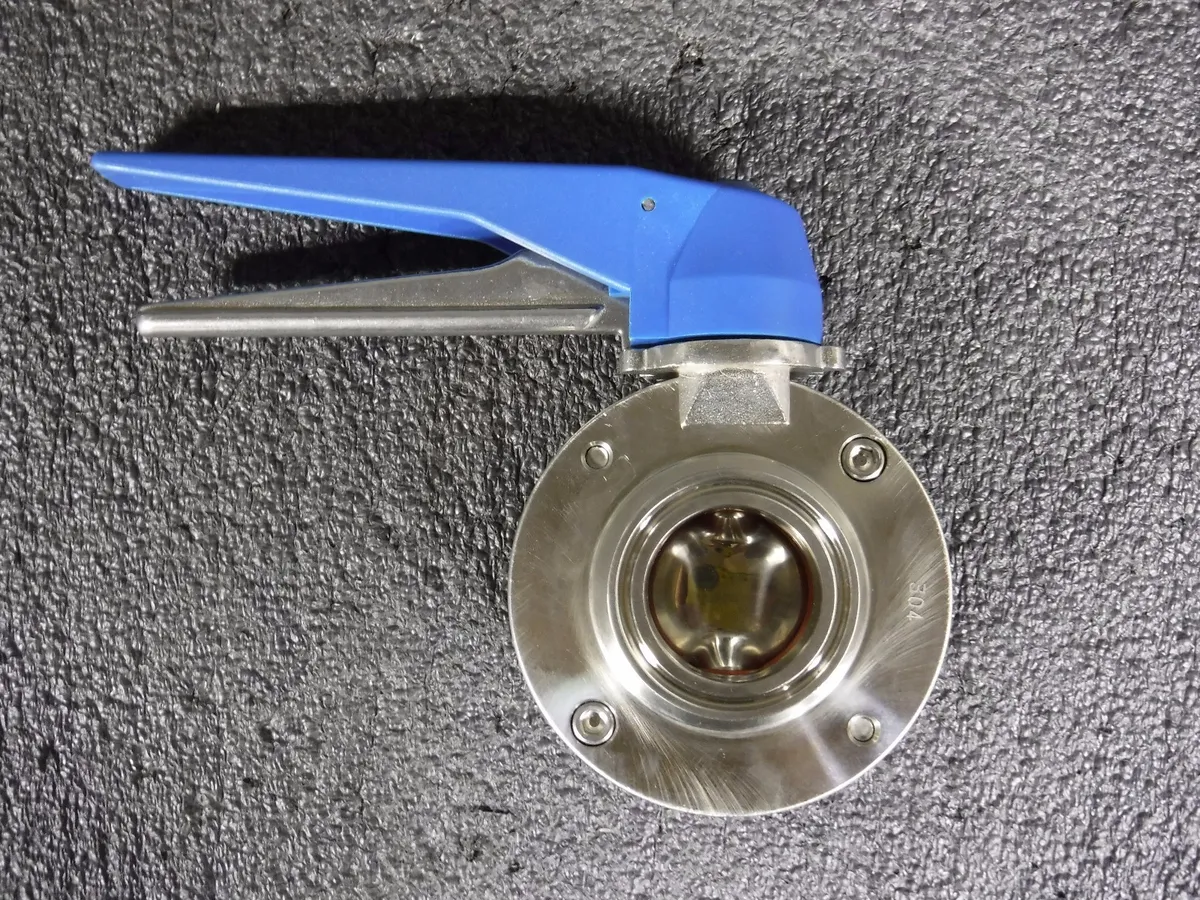

Size and type

Valves will depend on the sizes and types, determining the kind of use they will put into. You can adjust gas or fluid flow, divert, mix, or shut off flow. They can be used to avoid backflow and also to release pressure. The function of the valve will depend on which type of valve you choose. The usual valves include regulators, pinch valves, toggle valves, and check valves. You must match the valve’s size and type to its system to make the right choice.

Performance

A valve is expected for you to work under other pressure and temperature conditions. The best valve must work well under the system’s lowest and even the highest temperatures. Using metal valves is way better than plastic valves in high-pressure systems when temperatures are high. You know that metals are made stronger compared to plastics.

Select the materials

Valves are made from materials with different qualities like chemical resistance and strength. You must know the chemical and strength compatibility of the valve you choose. The valve must not react with the gases or liquid that flows through it. When you are dealing with harsh chemicals or corrosives, then using plastic valves is the best option you can use.

Maintenance

Choosing the suitable valve will only be completed by checking the maintenance. Valves are wearing out in time when you need to do maintenance and spend money to change the valve. It is necessary for valve reliability and stability, but working with the wrong valve will be dangerous, leading to gas or fluid leakages. You have to think about the connection type when you choose it because it will affect the speed and make the replacement easier.

Making your choice in finding a valve is now easier and faster. You must know where to start. All the information will help you make the best choice, specifically. You only have to understand the problems and application requirements of the system from the start before you make a choice.

Bite Down on Success: Why a High-Quality BJJ Mouthguard is a Must-Have for Grapplers

Brazilian Jiu-Jitsu (BJJ) is a martial art that demands concentration, discipline, and method. Whether you’re a seasoned practitioner or simply starting your Best BJJ Mouthguard, one piece of gear you ought to never train without is a reliable mouthguard. While it may appear to be a small addition to your gear, a high-quality BJJ mouthguard can make a significant difference in your training and overall success.

The following are several reasons why a BJJ mouthguard is essential for grapplers:

- Safeguarding Your Teeth and Mouth: BJJ includes close-quarter combat and grappling, where accidental impacts to the face are normal. A mouthguard acts as a barrier between your teeth and any external force, preventing chipped teeth, broken dental work, or slices to your lips and tongue.

- Diminishing the Risk of Concussions: An appropriately fitted mouthguard doesn’t only safeguard your teeth; it can also assist with decreasing the risk of concussions. By absorbing and dispersing impact forces, a mouthguard limits the shock transmitted to your head during hard takedowns or strikes, diminishing the risk of head wounds.

- Enhancing Breathing: High-quality BJJ mouthguards are intended to allow for clear and easy breathing. This is crucial during extreme training sessions or competitions when legitimate oxygen intake can affect your endurance and performance.

- Maintaining Concentration: Realizing that your teeth and mouth are safeguarded allows you to zero in on your methods and strategy without agonizing over potential wounds. This mental clarity can greatly contribute to your success on the mat.

- Compliance with Rules: Many BJJ academies and competitions expect participants to wear mouthguards as part of their safety regulations. Guaranteeing you have a suitable mouthguard on hand keeps you in compliance with these guidelines, forestalling any disruptions to your training or competition plan.

- Customization for Comfort: While over-the-counter mouthguards are readily available, custom-fitted mouthguards offer predominant comfort and protection. They are formed to accommodate your novel dental construction, giving a cozy and comfortable fit that won’t impede your speech or breathing.

- Long-Term Cost Savings: Putting resources into a quality mouthguard can save you money over the long haul. Dental methods to repair or replace damaged teeth are far more expensive than purchasing a mouthguard. It’s a wise investment in both your dental health and financial prosperity.

Picking the Right BJJ Mouthguard:

While choosing a mouthguard for Best BJJ Mouthguard, consider factors like material, fit, and thickness. Exclusively fit mouthguards are typically the most ideal option; however, in the event that you decide on an over-the-counter mouthguard, pick one intended for contact sports.

The BJJ mouthguard is not only an accessory; it’s a vital piece of defensive gear that each grappler ought to focus on. It guarantees your safety, limits the risk of dental wounds and concussions, and allows you to zero in on honing your abilities and achieving success in Brazilian Jiu-Jitsu. Don’t step aerobics on the mat without one; bite down on success with a high-quality BJJ mouthguard.

Why do june bugs come out in the summer? Exploring their seasonal habits

June bugs, also known as May beetles, are a common sight during the summer season. These insects belong to the scarab beetle family and are found across North America. They are named after the month they typically emerge from the ground, but why do they come out in the summer? Let us explore seasonal habits and shed light on their lifespan. As they are medium-sized beetles that measure around one inch in length. They have a shiny, brownish-black body with a few white markings on their wings. They are nocturnal insects and are commonly attracted to light sources. They are herbivores and feed on the leaves of trees and plants. They are not harmful to humans, but they cause damage to crops and gardens.

They have a seasonal life cycle that determines when they come out of the ground. The adult beetles lay their eggs in the soil during the summer months. These eggs hatch into larvae, which feed on the roots of plants and trees. The larvae then pupate in the soil and emerge as adult beetles the following summer. The emergence is also influenced by temperature and weather conditions. They tend to come out when the soil temperature reaches around 64 degrees Fahrenheit. This usually happens in late spring or early summer. They are more active during warm, humid nights, which is why they are commonly seen during the summer months.

The june bugs life span varies depending on their stage of development. Adult beetles typically live for around two to three weeks. During this time, they mate and lay their eggs in the soil. Once the eggs hatch, the larvae feed on the roots of plants for several months. The larvae then pupate in the soil and emerge as adult beetles the following summer. They have a relatively short life span, but they cause damage to crops and gardens during their adult stage. They feed on the leaves of trees and plants, which weaken the plants and make them more susceptible to disease and pests.

If you have a garden or crops that are being damaged by June bugs, there are several ways to control them. One method is to use insecticides that are specifically designed to target. These insecticides are applied to the soil or sprayed directly on the plants. Another method is to use physical barriers to prevent June bugs from reaching your plants. This includes placing netting over your garden or using sticky traps to catch the adult beetles. It is important to maintain healthy plants and soil to reduce the risk of damage from June bugs. Healthy plants are less susceptible to damage from pests and disease, and healthy soil supports the growth of strong, resilient plants.

They are a common sight during the summer months, but their seasonal habits and life span are not widely known. They emerge from the soil as adult beetles during late spring or early summer and are more active during warm, humid nights. Their life span is relatively short, but they cause damage to crops and gardens during their adult stage. By understanding their habits and life cycle, it is possible to take steps to control their impact and maintain healthy plants and soil.